Harlingen campus

the campus

latest news

Whether it's Automotive Technology, Diesel Equipment Technology, or Auto Collision and Management Technology, we have a program to suit your interests.

If you like to analyze and problem-solve, engineering could be a great career for you.

If you love helping others, then this is the career for you.

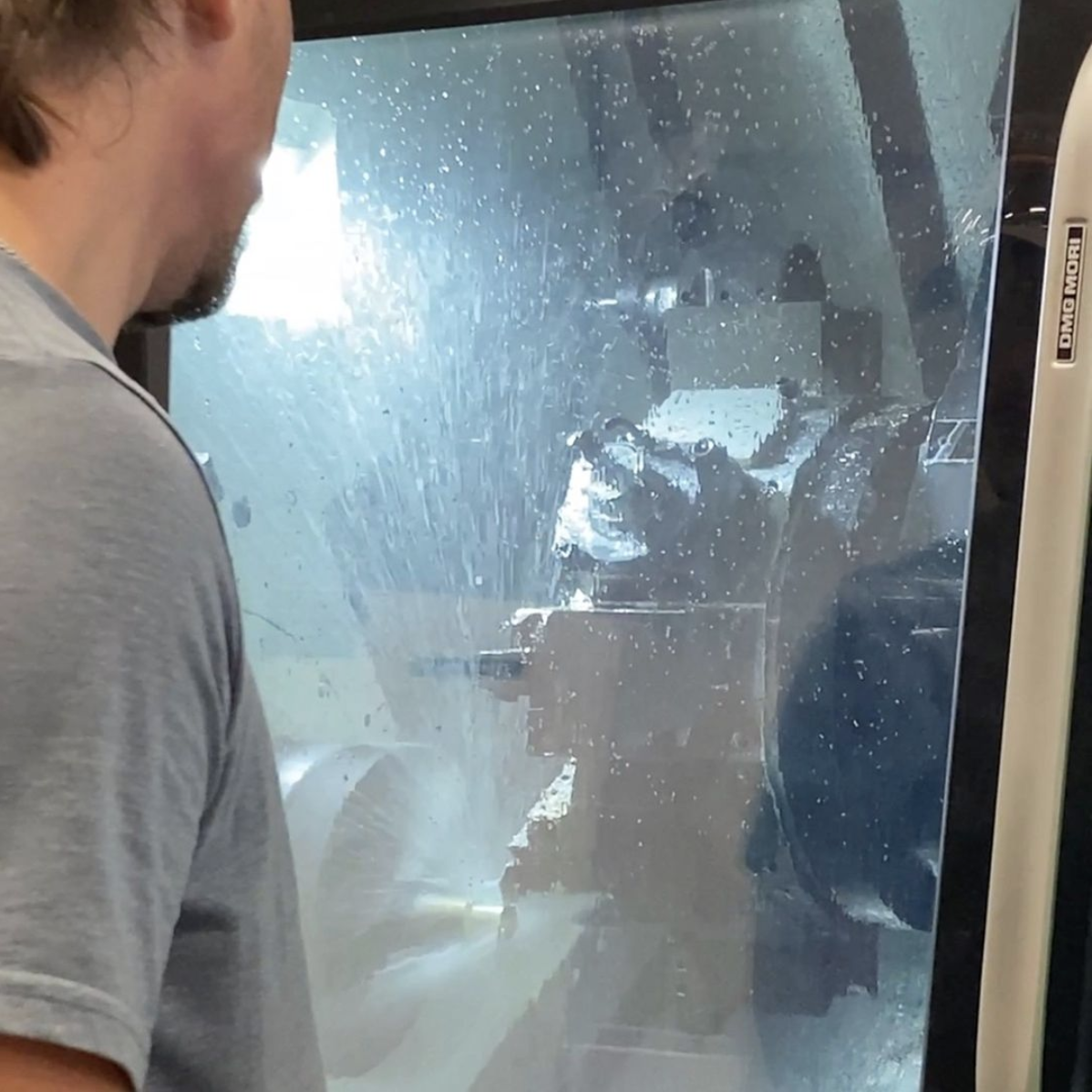

Learn from seasoned instructors on high-tech equipment, and launch yourself into a career that has sky-high potential.

Get a handle on HVAC, electrical construction or facilities management, and build the skills you need to learn a trade that will lead to a well-paying job.

Build skills that lead to a high-paying career using state-of-the art training facilities to become a lineworker or an environmental technician.

As one of our larger TSTC campuses, you’ll find everything you need to be a successful student. We offer the full suite of resources you’d find at any major university. Set in the beautiful tropical setting of Harlingen, you’ll enjoy walking through campus all year long.

As one of our bigger campuses, TSTC in Harlingen offers a wide variety of amenities. You’ll have full access to our Learning Resource Center, gymnasium, cafeteria, sand volleyball courts, outdoor seating, study rooms, student lounge, basketball courts, and more. We even have an online campus store for all your TSTC merchandise and supplies.

We encourage you to join in student housing and immerse yourself in new friendships, ideas and experiences.

At TSTC in Harlingen, you’re in the Rio Grande Valley of Texas, just 40 miles from the South Padre Island beach and just north of the Mexican border. You will experience the culture that is rich in the RGV area through local restaurants, festivals and more. Whether it’s the beaches on South Padre Island or the shopping in Mercedes, there’s always something to do.

@tstcharlingen

If you have information related to a crime, please submit a report. It will help us maintain a safe and secure campus environment for everyone.

Find out more information about safety on campus from our Clery Report.

Welcome Center

2424 Boxwood

Harlingen, TX 78550

Main Campus

1902 N. Loop 499

Harlingen, TX 78550

800-852-8784

Campus Hours

8 a.m.–5 p.m.

Monday–Friday